Linerless Labels: A Complete Guide to Waste-Free and Sustainable Labelling

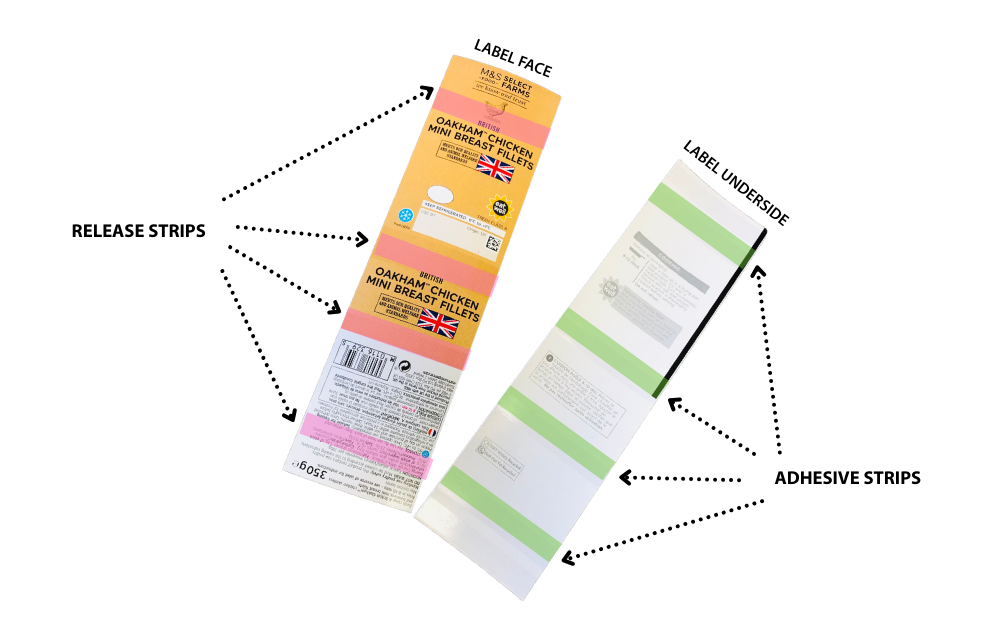

Linerless labels are pressure-sensitive adhesive labels supplied without a backing liner, making them a sustainable, cost-effective alternative to traditional self-adhesive labels. Using silicone release strips and adhesive zones, they self-wind and apply cleanly using Ravenwood’s Nobac applicators – eliminating waste and increasing efficiency. Ravenwood’s Circle of Linerless system ensures reliable performance from coating to application.

What Are Linerless Labels?

Linerless labels are a sustainable labelling innovation designed to eliminate traditional liner waste. Unlike self-adhesive labels that require a backing paper (liner), linerless labels are supplied on a continuous roll of pressure-sensitive material.

When applied using Ravenwood’s network of specialist printers and Nobac applicators, the label is cut or applied directly onto the product – reducing waste, improving efficiency and lowering environmental impact.

👉 VISIT OUR LABEL GALLERY

How Are Linerless Labels Made?

Linerless labels use a unique combination of release strips on the face of the label and pressure-sensitive adhesive on the underside. Linerless labels are precisely made using Ravenwood’s Com500 linerless coater, which applies pressure-sensitive adhesive on the back and release strips on the face in a controlled pattern. This combination allows the labels to self-wind without a liner while ensuring that only the adhesive touches the product during application. The Com500’s accurate coating, curing and rewinding systems make high-speed, consistent and reliable linerless label production possible.

-

Silicone release areas prevent layers from sticking together.

-

Adhesive strips align with tray edges or product surfaces.

-

This pattern allows labels to self-wind without a liner.

-

During application, only the adhesive touches the product.

-

Silicone zones ensure smooth separation on application.

-

This engineered coating pattern is essential for consistent, high-speed, reliable linerless performance.

👉 VISIT OUR COM500 PAGE

How Linerless Labels Work

Linerless labels use advanced substrates, adhesives and coatings to deliver performance without a liner.

| COMPONENT | FUNCTION | RAVENWOOD TECHNOLOGY |

|---|---|---|

| Substrates | Durable paper or film for strength and print quality | Ravenwood-approved materials for clarity and shelf impact |

| Adhesives | Pressure-sensitive, clean adhesion | Tailored to product surface and application |

| Machinery | Specialist linerless applicators | Nobac 5000 range |

| X-ray and vision inspection systems | VXR Vision Pack Inspection System | |

| Linerless converting equipment | Com500 Coater |

Ravenwood’s Circle of Linerless ensures all elements work together seamlessly – from coating to inspection and application.

👉 VISIT THE CIRCLE OF LINERLESS

The Benefits of Linerless Labels

Sustainability

-

Zero liner waste – no backing paper.

-

Lower carbon footprint – fewer raw materials.

-

Reduced transport impact – more labels per roll.

Efficiency

-

Longer roll lengths = fewer roll changes.

-

High-speed, clean application with the Nobac 5000 range of applicators.

-

Compact storage and reduced downtime.

Cost Savings

-

No liner disposal costs.

-

Less stoppage and higher uptime.

-

More labels per roll = lower shipping and warehousing costs.

Applications of Linerless Labels

Ravenwood linerless labels are trusted across industries:

-

Food: ready meals, bakery, meat, fish, poultry, fresh produce.

-

Logistics & Retail: wholesale packaging, promotional labels.

-

Beverage: bottles, cartons, cylindrical products.

High adhesion, print quality and compatibility support demanding environments.

Comparison: Linerless vs Self-Adhesive Labels

| FEATURE | LINERLESS LABELS | SELF-ADHESIVE LABELS |

|---|---|---|

| Liner Waste | None | Backing liner discarded |

| Roll Length | Up to 40% more | Limited by liner thickness |

| Downtime | Reduced | Frequent roll changes |

| Environmental Impact | Lower CO₂ | Higher CO₂ |

| Cost Efficiency | Improved | Higher lifetime cost |

| Storage & Transport | Compact | Bulkier, heavier |

Nobac 5000 Range of Linerless Applicators

At the centre of Ravenwood’s linerless ecosystem is the Nobac 5000 range, designed specifically for precision, reliability and high-speed linerless label application.

Key benefits:

-

Handles multiple label formats and tray styles.

-

Integrates with barcode printing, weigh-price systems and vision inspection.

-

Built for demanding food production environments.

-

Part of the Circle of Linerless workflow.

👉 VISIT OUR NOBAC FAMILY TREE

Case Studies

Ravenwood’s linerless solutions are used worldwide to reduce waste, streamline operations and enhance branding.

Read examples in:

-

Supermarket-ready packaging.

-

High-speed food production lines.

-

Brands moving from self-adhesive to linerless.

👉 VISIT OUR CASE STUDY PAGE

Frequently Asked Questions About Linerless Labels

Q: Can linerless labels be used on any product?

A: Yes – linerless labels are compatible with many shapes, substrates and packaging formats.

Q: Do linerless labels require special equipment?

A: Yes – they require dedicated applicators such as Ravenwood’s Nobac 5000.

Q: Are linerless labels more expensive?

A: The initial setup may be slightly higher, but long-term costs are significantly lower due to reduced waste and increased uptime.

Q: Can linerless labels be recycled?

A: Yes – Ravenwood-approved materials support recycling and circular packaging initiatives, helping to reduce CO₂ emissions.

👉 VIEW OUR ENVIRONMENTAL PAGES

Ready to Go Linerless?

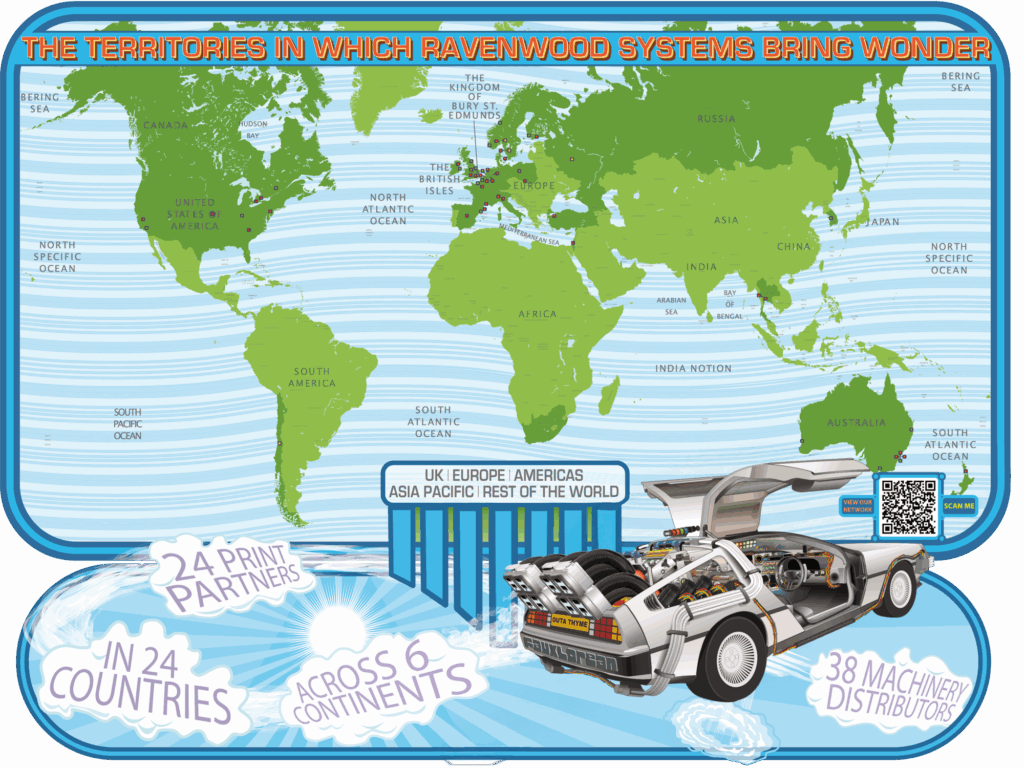

With a global network of machinery distributors and printers, we’re helping brands worldwide transition to sustainable, waste-free labelling. Join the movement and be part of the future of responsible branding.

👉 GET IN TOUCH TODAY

Ravenwood’s Global Machinery & Printer Network

Delivering linerless label solutions worldwide through trusted partners.

Our Network at a Glance

-

Ravenwood works with a carefully selected network of machinery distributors and printer partners across the globe.

-

Together, we deliver reliable, high-performance linerless solutions to food, beverage, retail and logistics industries.

-

Key stats:

-

24 countries served – across 6 continents

-

38 certified machinery distributors and 24 printer partners

-

👉 FIND YOUR LOCAL DISTRIBUTOR