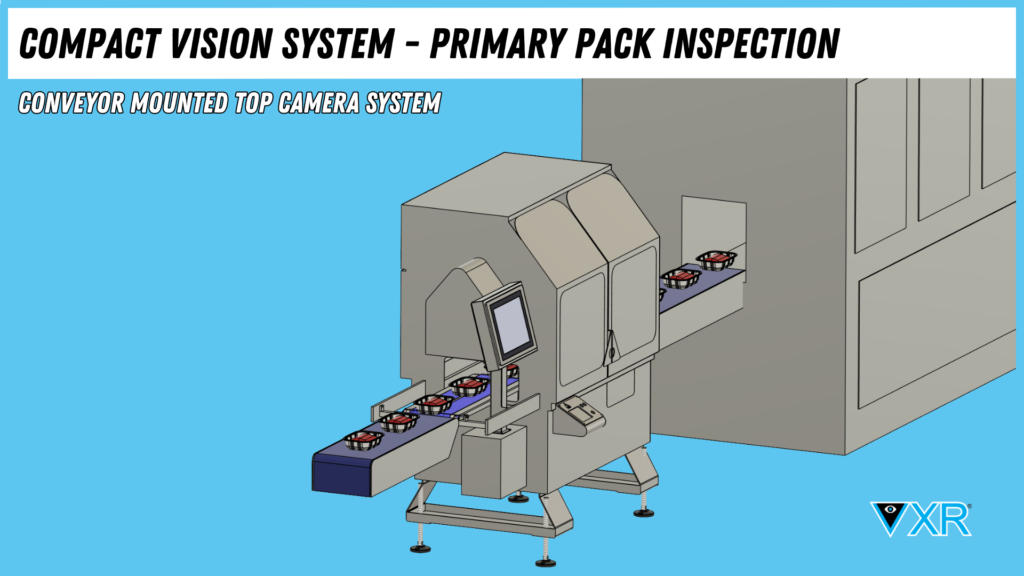

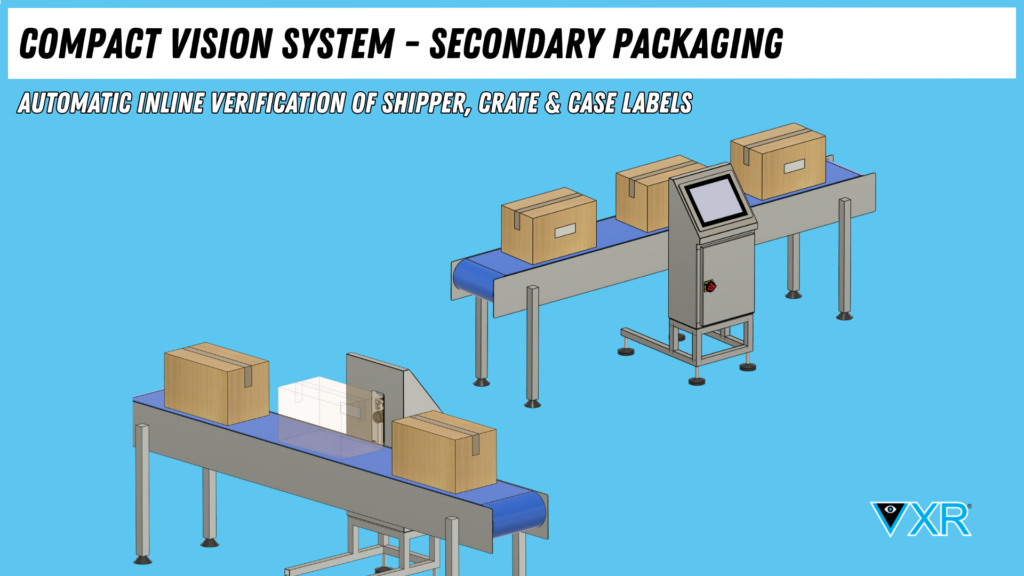

Expanding the boundaries of its Vision technology, Ravenwood Packaging has unveiled a new compact Vision system designed for space-constrained production environments in mind. Engineered to integrate seamlessly with the Nobac 5000 outfeed belt (or virtually any other conveyor system) the bolt-on unit delivers the power of Ravenwood’s advanced inspection capabilities in a compact and streamlined form.

This latest addition to Ravenwood’s Vision universe follows closely on the heels of several major innovations, including the launch of the VXR Seal Contamination Detection System and recent upgrades featuring Anti-Reflection and Deep Learning enhancements.

The Ravenwood Compact Vision System offers a robust alternative to traditional smart camera setups, which may in some applications, fall short in high-demand environments. Despite its compact design, the unit retains the full functionality of Ravenwood’s standalone Vision system, including reject signal output and shared core components with the VR and VXR models – delivering 4K image quality, high precision processing and image storage.

Ideal for manufacturers seeking reliable inspection in limited spaces, Ravenwood’s new Vision system reinforces the company’s reputation for pioneering, space-efficient quality control solutions.

For further information, contact Ravenwood’s marketing team on +44(0)1284 749144.