It’s all systems go! The leaders in linerless and pack inspection will be exhibiting at Interpack in Düsseldorf. Ravenwood will be demonstrating the Nobac 5000V vertical linerless applicator, Nobac 5000A automatic linerless applicator and VR Vision System, for automated optical inspection on food products.

All three machines are standalone but the 5000A and VR can be linked for label application and automated optical inspection. Ravenwood will also be demonstrating a revolutionary quality management system. A representative from QUOR will be joining Ravenwood on their stand for showing how this software communicates with the VR Vision system.

Let’s take a look at the systems Ravenwood will be demonstrating at this year’s show.

Nobac 5000V Vertical Linerless Applicator

Ravenwood is excited to showcase the all new Nobac 5000V. Unlike other machines that fall under the Nobac 5000 range, this particular applicator features the mandrel to the side of the product conveyor, changing it to a vertical labeller. Essentially, products are driven ‘through’ the label, so allowing for difficult applications and increased protrusions. Subsequently, this particular model is ideal for the labelling of whole birds.

Although, the 5000V is restricted to applying C Wrap linerless labels, it can label a variety of MAP and VSP trays, as well as shrink wrap. A maximum pack height of 125mm applies with excellent application speeds at over 80ppm.

There is also the option to link to weigh scales, as well as printing catch weight and fixed weight products.

Nobac 5000A Automatic Linerless Applicator

Ravenwood will also introduce and showcase its automatic linerless applicator, the Nobac 5000A. Building its core foundation on the Nobac 5000 range, the new automatic sleever is a customer optional addition that automates switching between products, pack sizes and label size. This is thanks to its motorised adjustment of top lay belts, infeed guides and height adjustment.

Operators, factory management software and weigh-price labellers can select pre-programmed tray sizes to allow the machine to move automatically, to new positions, freeing up time for the operator to load labels. The Nobac 5000A will be linked to the VR Vision system.

VR Vision System – Automated Optical Inspection

Joining the 5000A is Ravenwood’s VR System. Both machines will be linked for demo purposes to show label application on the 5000A and then pack inspection on the VR. Once the food pack has been labelled and travelled through the 5000A, it will be analysed by the Vision system. With unrivalled inspection and quality assurance software, the VR utilises the latest image processing technologies to analyse each finished pack when leaving the production line.

As mentioned, the VR has been built as a standalone technology but can also be integrated into a line system. Each pack is individually inspected against a pre-set standard, programmed into the user-friendly interface. Any packs that fail to meet the set criteria are automatically rejected into a secure bin with the reject confirmed and recorded for tracking.

Bar codes, use-by dates and traceability codes are analysed and confirmed without the need to interrupt the packs whilst in flight. In addition to these checks, 2D codes for encoded stock rotation or label ID can be read on-line.

Pack speeds up to 130 per minute are achievable to perfectly match any existing line processing equipment. The VR also has the ability to integrate an upstream checkweigher. This allows for all rejected packs to be collected in one area, but in separate bins.

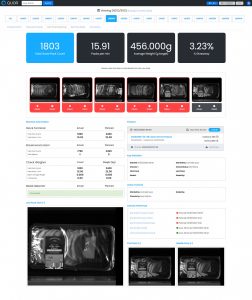

QUOR Quality Management System

QUOR’s revolutionary quality management software will be working in synergy with the VR system. The software makes compliance straightforward, paperless and easy to operate.

The QUOR management system integrates seamlessly for all manual inspections and processes including on-line quality checks that would otherwise be entered manually. QUOR can talk to the VR Vision system for criteria such as in-line recording, verification and product checks, for complying with the VR’s existing software.

QUOR allows for product selection and storage of quality data. Products are selected for checking on the QUOR interface resulting in the VR being automatically set up without further intervention. All line quality data is uploaded, captured, stored and reported for analysis, and traceability. Images of all packs produced including rejected packs are recorded and retrieved to further enhance quality assurance and for satisfying audit processes. Retailer compliant KPI reports generated and submitted are available at the click of a button. Data is retrieved securely both on and offsite, via PC based software or the QUOR quality management app.

Imagine having your KPI report available in real time – anytime and anywhere? Well, the QUOR system does just that.

Interpack 2023

Interpack is reported to be the world’s largest trade fair and a global trendsetter for the packaging sector. From sustainability to digitalisation, the focus is on packaging materials, packaging machines and related process technology. Market sectors include food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial. Interpack 2017 experienced record breaking numbers with 2,865 companies exhibiting.

Find team Ravenwood in Hall 08B | Stand 8BD35. Visit Ravenwood’s Exhibitor Portal>

For further information, contact Natalie in Marketing on +44(0)1284 749144.