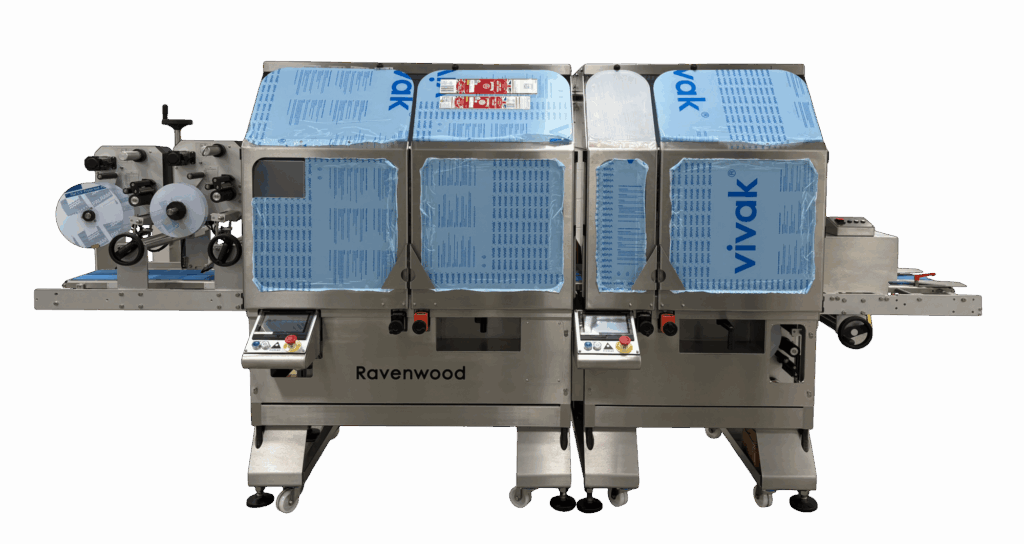

Our latest customer Twin Head installation showcases a fully optimised labelling setup, designed for high-speed steak pack applications.

INTEGRATION: Nobac 5000T Twin Head + Two Top Flash Labellers + RFID/RF Tag Base Labeller + Gapping Infeed Conveyor + 800 Outfeed Conveyor

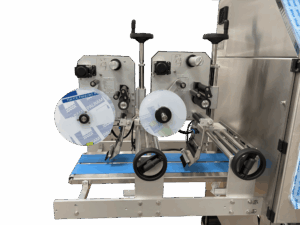

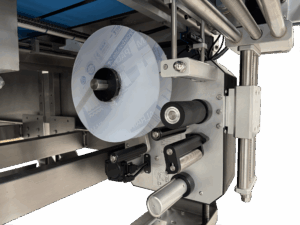

- This system features twin Nobac 5000 linerless applicators for maximum efficiency, paired with two Top Flash Labellers to apply promotional labels seamlessly – ensuring minimal downtime during reel changeovers.

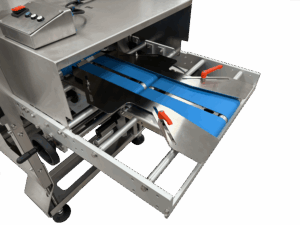

- An integrated RFID/RF Tag Base Labeller applies hidden RFID or RF tags to the base of the tray, underneath the linerless label, delivering an effective anti-theft and traceability solution. These tags can be encoded with product data, enabling supply chain tracking, inventory management, and enhanced retail security — all without affecting pack aesthetics.

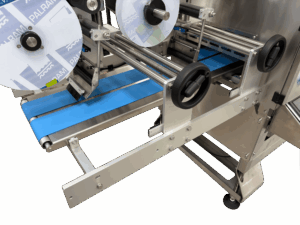

- To maintain precise product flow, a Gapping Infeed Conveyor ensures consistent pack spacing, while an 800 Outfeed Conveyor supports the dual Top Flash Labellers.

- Configured for D-wrap linerless labels, this bespoke setup demonstrates our customer’s investment in advanced and flexible labelling technology.

NB: This is the actual machine supplied to the customer, shown with its protective plastic covering.