We have launched a linerless CO2 savings calculator to show you just how much CO2 can be saved when comparing self-adhesive labels to Ravenwood linerless labels.

Before we get to the calculator, lets summarise self-adhesive and linerless.

What is the difference between self-adhesive and linerless?

There is one major difference. Self-adhesive labels feature backing paper whereas linerless labels do not. Let’s explain both.

Self-Adhesive Labels

As we have said, self-adhesive labels feature backing paper or liner, and this carries the adhesive for the face material of a pressure sensitive label. The liner also has a release coating applied that prevents the adhesive from sticking to the liner. This coating is made from silicone which allows the face material and adhesive to be removed together when a label is applied to a pack. The liner protects the adhesive and the label itself during the cutting, storage and printing processes.

On doing our research, we found that a total of *2,200kgs of CO2 per tonne is emitted to produce 1,000kgs of liner paper (source: AWA and Avery Dennison). This figure and its mathematical equations, form the core of our linerless CO2 savings calculator.

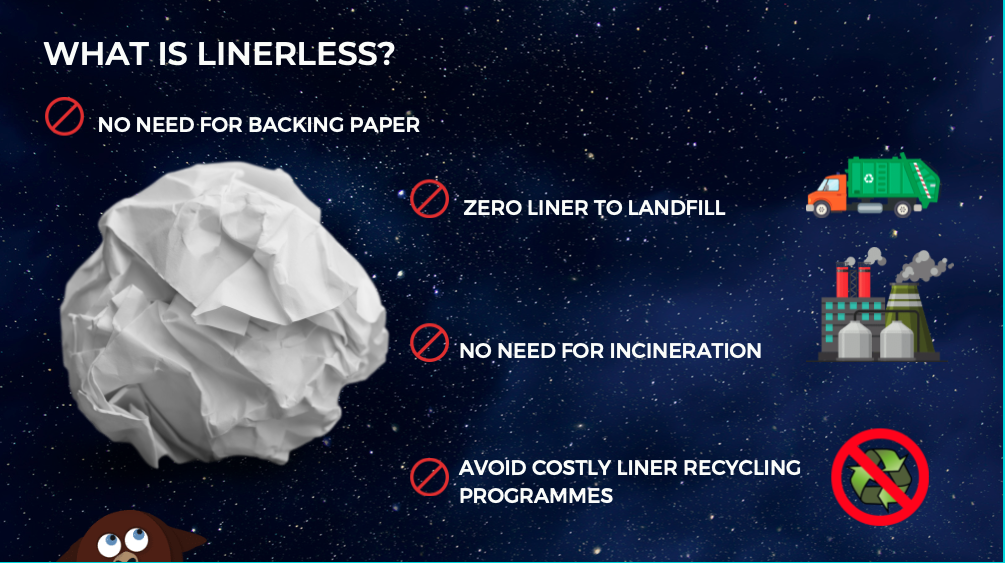

There are also further costs to consider. After the application process in the factory, there will be large amounts of the release liner to dispose of. Release liners are one of the biggest waste factors in the printing industry. Backing papers cannot currently be recycled, due to the silicone layer required to protect the adhesive. Subsequently, the only options are to landfill, incinerate or opt into expensive liner recycling programmes.

In summary: Release liner is a costly business not only to the environment but also your pocket. When you consider the release liner manufacturing process coupled with further emissions and costs incurred, for its disposal or recycling. Production + waste disposal / recycling = massive amounts of CO2 emissions.

Ravenwood Linerless Labels

Linerless is a pre-printed pressure sensitive label that does not carry a backing paper or release liner. There are no costs to the planet for manufacturing a material (release liner) that is not needed. And the good news is, after the reel of labels is utilised in the factory, the only waste to be disposed of is the cardboard inner core. This is widely recyclable.

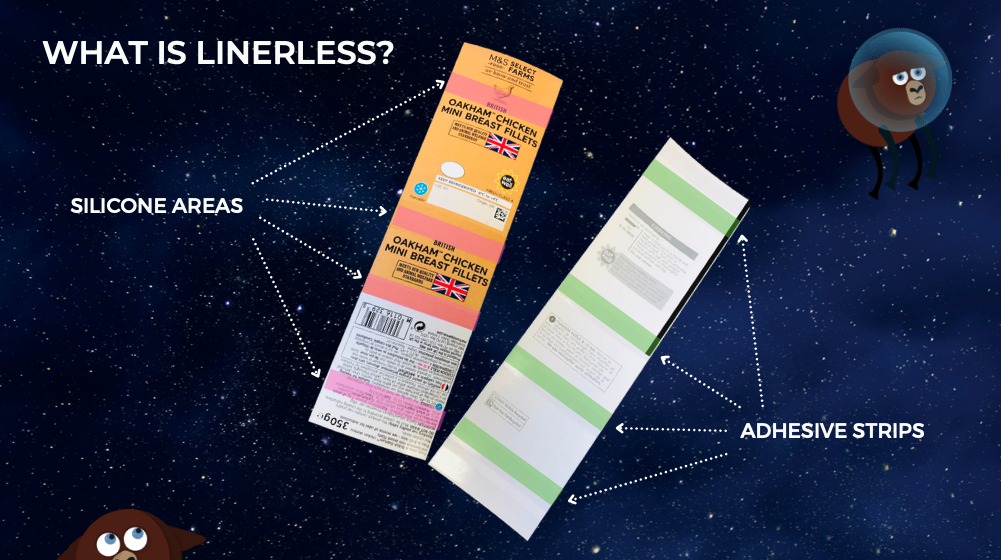

Linerless labels are wound on a roll or reel – similar in this respect to self-adhesive labels but instead of relying on a backing paper to separate the adhesive from the label above, linerless labels feature silicone strips to the face and adhesive strips to the back – in exactly the same position. This enables the reel of labels to stick to itself without the need of a release liner (barrier) to do this.

Due to the absence of the liner, it is possible to fully print on both sides of the linerless label. If this was done on the self-adhesive label, the reverse print would deaden the adhesive and it would not stick. This allows more surface area on the linerless label for additional product information.

In summary: With no need for a liner or its manufacturing process, we have zero CO2 emissions incurred and then subsequently zero emissions that would otherwise have been caused by the disposal / recycling of the liner. Linerless has no need for backing paper and is kinder to the planet as well as your finances.

The Ravenwood linerless labels CO2 savings calculator mission

Ravenwood embarked on a fresh linerless mission and researched how much CO2 is emitted when manufacturing a tonne of backing liner for self-adhesive labels. As mentioned earlier, we found that a total of 2,200kgs of CO2 per tonne is emitted to produce 1,000kgs of liner paper (source: AWA and Avery Dennison).

Our CO2 calculator is simple with instructions to guide you along the way but in brief, this is how we do the math:

- Simply enter measurement A (the longest of the lengths) and measurement B (the shortest). Then hit the ‘calculate’ button.

- Our calculations are based on 3, 4 and 5 adhesive / silicone lines.

- CO2 savings are displayed in kgs.

Check out our linerless CO2 savings calculator by clicking on the button below and see how much CO2 you could potentially save!